Request for Quote

Spindle Repair

An integral part of various industrial machinery, spindles experience long operation periods, leading to general wear. Defective spindles can cause a host of challenges in production machinery, like higher operating costs and reduced production, or if left unrepaired, it can cause total machine failure. IBAG North America offers precision spindle repair services to provide spindle system solutions and keep your operation running smoothly. Learn about premium CNC spindle repair from IBAG, discover the advantages, and understand the procedures of our methodology.

When done with an expert hand, a high speed spindle rebuild or spindle repair can also offer long-term benefits, such as lower operating costs and high-quality repairs that provide machine longevity. A spindle needing repair may not be immediately evident, but damaged spindles will disrupt the machining process and cause inefficient operation with higher costs. With our premium precision spindle repair services, we replace defective spindle parts using our informed proprietary methodology. Our experienced technicians provide high-quality spindle repair services with extensive testing and procedures that ensure all rebuilt IBAG spindles perform with exceptional reliability following a repair.

Service Request

Be sure to read the Spindle Repair Shipping Instructions.

CNC Spindle Repair Services Advantages

Receiving spindle repair services from knowledgeable and experienced technicians at IBAG North America provides your machinery and operation with a range of benefits. Aside from the initial repair, high-quality precision spindle repair offers production success and minimizes critical downtime. Spindles are a vital component in production machinery, and when components stop working as intended, it can cause the machine to slow down, require costly and timely repairs, or, in the worst case, become inoperable.When done with an expert hand, a high speed spindle rebuild or spindle repair can also offer long-term benefits, such as lower operating costs and high-quality repairs that provide machine longevity. A spindle needing repair may not be immediately evident, but damaged spindles will disrupt the machining process and cause inefficient operation with higher costs. With our premium precision spindle repair services, we replace defective spindle parts using our informed proprietary methodology. Our experienced technicians provide high-quality spindle repair services with extensive testing and procedures that ensure all rebuilt IBAG spindles perform with exceptional reliability following a repair.

IBAG Spindle Repair Process

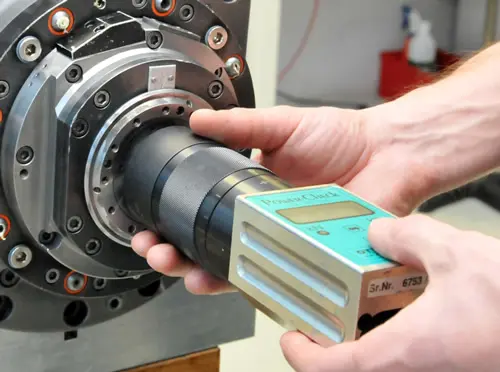

For all IBAG high-speed spindles, we offer repair, installation, and rebuilding services. Spindle repair services, including bearing replacements, balancing, and run-in and vibration testing, are completed at our state-of-the-art facility in North Haven, Connecticut. The premium CNC spindle repair process from IBAG North America is as follows:- The spindle undergoes a thorough evaluation to determine the spindle condition and the suspected cause of failure. Photos are taken, and observations are recorded in a repair report. We will provide a detailed cost proposal, including all parts and labor required for spindle repair services.

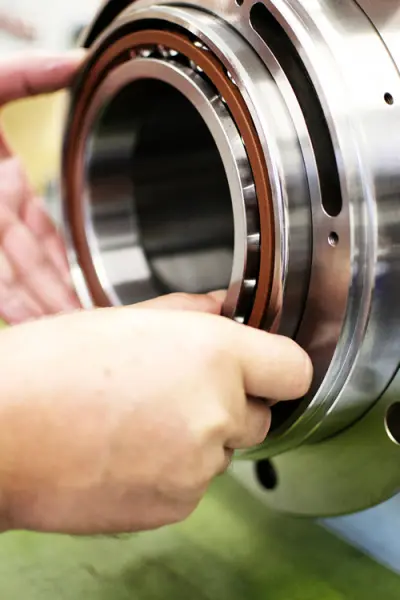

- Once approved, the spindle is disassembled, and internal parts are assessed for wear. Then, internal spindle components are cleaned in a hot, ultrasonic cleaner and dried.

- If necessary, the spindle rotor shaft is checked and rebalanced to less than a G1 level with a precision balancer.

- The spindle is reassembled with new parts and bearings following exclusive procedures set forth and required by the factory. Following assembly, the spindle enters a test field area for run-in, balancing, and final testing.

Spindle Parts and Supplies

In addition to IBAG high-speed spindle repair, all spindle system components are supported by our repair services and spare parts capabilities, including high-frequency spindle drives, chillers, bearing lubrication systems, and additional components. All spindle repairs carry a six-month warranty, including bearings.Experts in High Speed Spindle Rebuild and Repair Services

For over 25 years, IBAG North America has offered expert rebuilding and repair services for high-speed spindles. When repairing spindles, experience is essential to success. Spindle repair services require the disassembly and reassembly of integral components and should only be completed by professionals to ensure proper operation. With combined expertise spanning decades, IBAG North America offers reliable spindle repairs from knowledgeable technicians.Contact Us for Premium Spindle Repair You Can Trust

IBAG North America is headquartered in a high-technology facility in North Haven, Connecticut. From our headquarters, we offer a vast inventory of high-speed spindles and spindle system components, application engineering, and premium repair services for CNC spindles from expert technicians. Contact IBAG North America with any questions, give us a call, or submit your service request below.Service Request

Be sure to read the Spindle Repair Shipping Instructions.