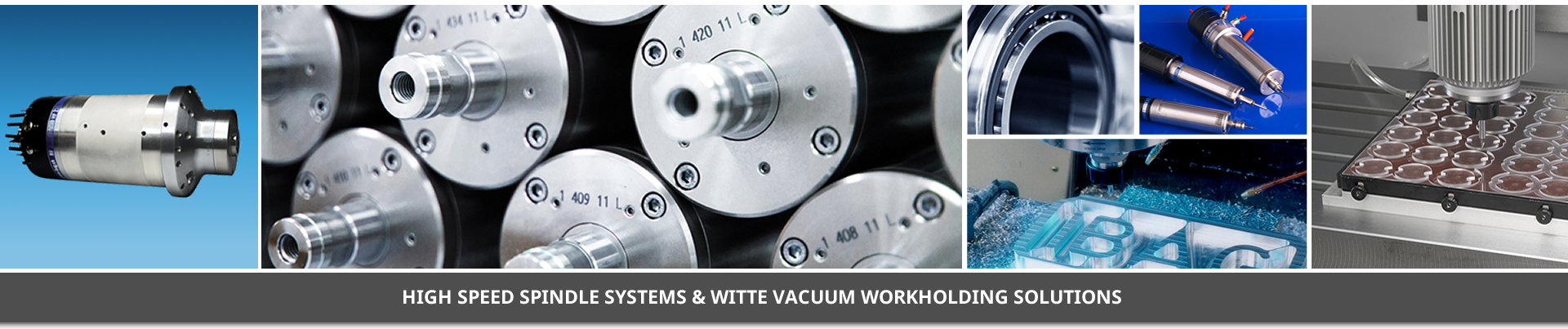

Since ancient times, tool holding has served a critical task: to facilitate the spindle's ability to quickly remove metal to produces a finished part. This blog explores tool holding's history and methodologies.

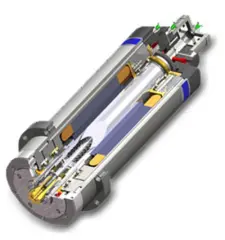

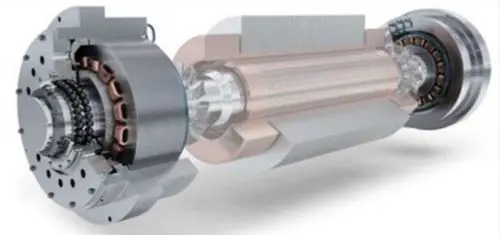

Learn the evolution and features of spindle motors - from shop belts to modern synchronous technology for high-speed machining.

Learn about the latest trends in spindle manufacturing designed to increase speed, feeds and production.

Keep your high speed machining operations up and running efficiently by avoiding these common mistakes.

As a leading supplier of high speed spindles, we get a lot of questions about them and their use. Check out the most common ones to see if yours are answered.

Many parts are made lathes instead of milling machines, and can be held using vacuum chucks. So, how do we make sure a rotating vacuum chuck will work? What are the differences?

Learn the perfect recipe for high speed machining by understanding and optimizing for the key ingredients for various applications and materials.

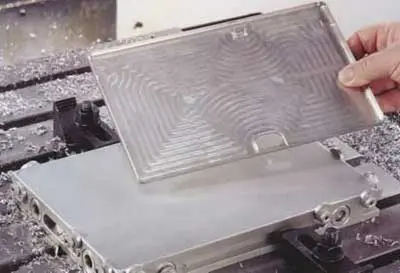

There are many methods to hold parts while they are being machined. Learn the basics of the vacuum workholding approach.

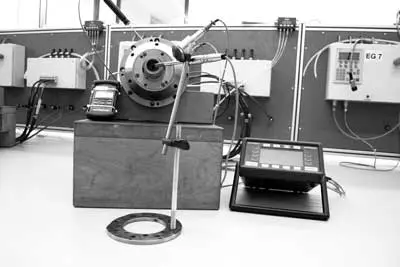

Avoid costly issues such as reduced bearing life and spindle damage by understanding the need for a properly balanced spindle.

Learn about porous vacuum chucks, how they work and their specialty applications.

Learn the major differences between standard high speed spindles and today's ultra speed spindles.

Multiple spindle systems can be designed to solve a variety of problems. In this blog, we illustrate several examples of how where they are used to solve various production challenges.