Witte Vacuum Workholding Products

IBAG Has Witte Vacuum Workholding Systems And Parts For CNC Machining & Milling

Vacuum workholding systems provide the hold and precision required for high-speed machining and milling applications. IBAG is proud to be North America’s premier Witte Vacuum Workholding System Distributor for CNC machining, milling and turning applications. Witte is a renowned German manufacturer of high-quality vacuum workholding chucks, pumps, and accessories. We offer a wide variety of vacuum chucks designed to satisfy most milling and turning applications. If your parts vary from small to large, require high accuracy or have other demanding specifications, we can provide a vacuum clamping system that is dependable, cost-effective, and available with fast delivery.

Learn more about our selection of high quality Witte vacuum pumps, chucks and components below, Request for Quote on Witte products or Contact Us with any questions.

Witte vacuum pumps and chucks have a reputation for high quality and come in multiple sizes and configurations to accommodate small to large workpieces.

Witte Vacuum Workholding System & Component Selection

IBAG offers a broad range of standard, in-stock and custom vacuum chuck solutions for precision milling and machining. Vacuum workholding products are available in multiple sizes and configurations to accommodate small to large workpieces.

Witte Modular Vacuum Pumps

| No. | Type | Suction Capacity | Motor V/kW | Max. mbar | dB (A) | Lxwxh Mm | Kg |

|---|---|---|---|---|---|---|---|

| 80172 | Modular Pump | 6 | 230/0.37 | 50 | 59 | 500x630 | 25 |

| 80173 | Modular Pump | 6 | 400/0.37 | 50 | 56 | 500x630 | 25 |

| 82147 | Modular Pump | 16 | 230/0.55 | 20 | 60 | 500x630 | 31 |

| 82146 | Modular Pump | 16 | 400/0.55 | 20 | 60 | 500x630 | 31 |

| 80174 | Modular Pump | 21 | 230/0.75 | 20 | 62 | 500x630 | 45 |

| 80175 | Modular Pump | 21 | 400/0.74 | 20 | 62 | 500x630 | 45 |

| 82150 | Modular Pump | 63 | 400/1.5 | 20 | 65 | 600x600x1030 | 95 |

| 83467 | Modular Pump | 100 | 400/3 | 20 | 67 | 700x700x1130 | 113 |

Witte Liquid Ring Vacuum Pumps

| No. | Dimensions | Suction Capacity | Motor V/kW |

|---|---|---|---|

| 93801 | 463x432x602 | 22m3/h | 3 ph. 400V 50/60 Hz, .83/1.06kW |

| 93802 | 515x572x743 | 45m3/h | 3 ph. 400V 50/60Hz, 1.2/1.6kW |

| 93803 | 515x572x743 | 65m3/h | 3ph. 400V 50/60Hz, 2.4/3.5kW |

| 93804 | 525x620x920 | 100m3/h | 3ph. 400V 50Hz, 4kW |

| 93805 | 710x845x1100 | 150m3/h | 3ph. 400V 50Hz. 4kW |

| 93806 | 710x845x110 | 198m3/h | 3ph. 400V 50Hz, 5.5kW |

| 93807 | 710x845x110 | 232m3/h | 3ph. 400V 50Hz, 7.5kW |

Witte Vacuum Systems & Pumps

Vac Mat Systems

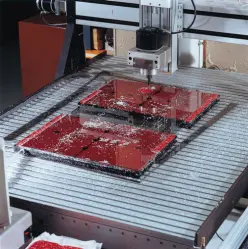

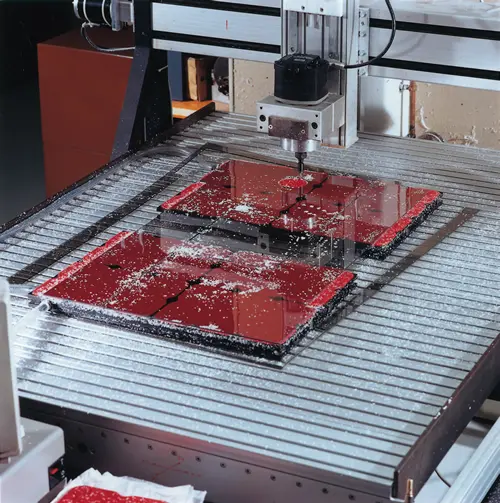

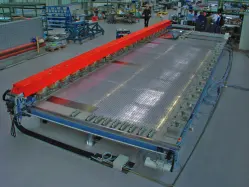

Specially molded plastic mats create a modular, universal workholding fixture for precision milling. Each vac mat system measures 200 x 300 mm and works best for parts larger than 150 x 150 mm. Larger configurations are possible.Aluminum Flip Pod Vacuum Systems

Aluminum flip pod workholding systems are designed to secure large work pieces on big machines. These configurable vacuum holding systems work well for most machine types and sizes and help minimize setup changeover times.Witte CNC Vacuum Pumps

We offer dry, air-cooled, and oil-lubricated vacuum pumps with capacities from 3 CFM to 500 CFM. Special units are also available for larger workholding applications.Round Grid Type Vacuum Chucks

Achieve high holding force with round grid-type vacuum fixtures. The universal design replaces many dedicated vacuum chucks and allows clamping of smooth or rough materials. Available in sizes up to over 800 mm in diameter and special sizes and configurations.Witte CNC Vacuum Pump Features

The specific capabilities of each Witte vacuum system vary by the pump type or model. Pumps range in capacity from small handheld models to entire vacuum workstations. Some advantages of Witte vacuum pumps include but are not limited to:- Reliable in continuous operation

- Easy to maintain

- Modular unit has integrated liquid separator

- Space saving assembly for easy access

- Integrated air filter, safety valve

- Pumps from 5m3/h to over 500m3/h, also on request dry running pumps

Witte Vacuum Chucks

Small Parts Vacuum Chucks

These chucks are constructed of aluminum and feature a slotted base and special adapter pads for securing small parts for light milling and drilling. Small part vacuum chucks also secure pieces larger than 25 x 25 mm for fine milling and engraving applications.High Precision Micro Porous Chucks

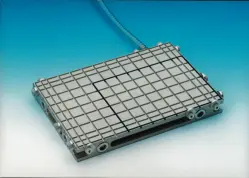

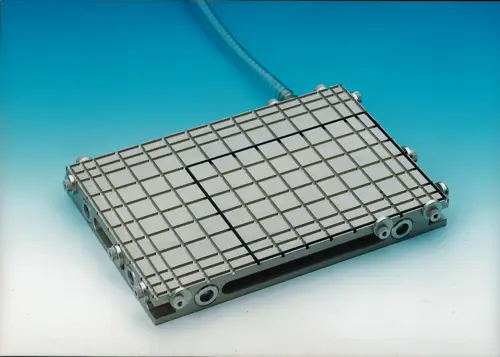

Micro porous chucks are constructed of ceramic, Metapor, porous aluminum, and sintered bronze and are designed to clamp thin workpieces with high accuracy. These chucks are best suited for the light, dry processing of foils, films, paper, and thin metal strips.High Precision Grid Type Chucks

This high precision grid type chuck style offers the strongest and most accurate method of workholding. We offer rectangular styles for milling and grinding, and circular styles for CNC lathes.Ice-Vice Freeze Chucks

Designed for small or intricate work pieces, freeze chucks provide incredible holding accuracy without inducing stress on the part. Use Witte Ice-Vice Freeze chuck systems in R&D laboratories or high-volume manufacturing of electronics, optics, and medical devices.Witte Vacuum Specials

We offer a range of Witte vacuum products for specialty applications. Options include 3D chucks for aerospace, custom vacuum chucks, friction-stir welding chucks, and semiconductor and wafer chucks for inspection systems. We’ll help you find a custom vacuum workholding solution for your application.Witte Vacuum Chuck Material Options

Witte stocks a variety of chucks to accommodate your requirements and clamping operations. Chucks are compatible with Witte vacuum supply units and can be used alongside existing vacuum systems. Certain chuck material is available only upon request, with common materials including:- Steel

- Aluminium

- Plastic

- Ceramic

- Sintered Bronze

Vacuum Chucks For CNC Machining Processes & More

IBAG can supply Witte vacuum clamping systems in over 27 variations and sizes available as pumps or units. Vacuum workholding systems can be used for CNC machining, milling and turning operations that are subject to high repeatability. Popular applications for vacuum workholding systems include:- Machining (milling, turning, drilling, grinding)

- Engraving

- Polishing

- Deburring

- Coating

- Printing

- Irradiation

- Measuring (tactile, optical)

- Testing, simulating

- Moving and positioning

- Friction-stir welding

- Laser welding processes

- Visual analysis

Why Choose IBAG For Industrial Vacuum Pumps and Chucks

IBAG offers quick delivery on a wide range of modular standard Witte vacuum products that can be easily configured for your parts. The proper vacuum workholding system for your application will be determined by workpiece size, tolerance, and the machining process required on your parts.IBAG also offers a variety of Witte vacuum pumps and liquid separators, including modular designs (pump plus liquid separator) and liquid ring pumps. Industrial vacuum pumps are available in various voltages in both single and three-phase configurations.

IBAG also offers repair services for your vacuum systems. IBAG North America has a full tool room, including CNC milling, grinding and turning equipment. If necessary, heavily damaged chucks can be returned to the factory for repair.

Precision Vacuum Chucks for Milling and CNC Machining

For milling applications, Witte vacuum chucks can be supplied in many sizes to fit most standard milling machine tables. For lathes, round chucks are available in many diameters for both horizontal and vertical turning applications, along with suitable rotary couplings.Advantages of Witte Workholding Vacuum Products

Witte has vacuum pumps and pump components available in several designs to meet each application requirement. Witte vacuum products provide a cost-effective solution to vacuum workholding, with off the shelf and custom workholding systems available. Configuring off the shelf components can effectively provide accurate vacuum workholding to reduce lead time and lower machining costs. Witte also offers custom vacuum workholding solutions such as dedicated chuck designs for parts that cannot be held with standard products. Frequent customization options include:- Chucks to Hold Small Parts

- Parts Requiring High Accuracy

- Complex Layouts

Contact IBAG North America for Custom Witte Vacuum Workholding Products

Contact IBAG today to discuss your unique workholding challenge. Contact our team of application specialists that will evaluate your application and recommend the correct Witte vacuum workholding system to satisfy your needs by calling 203-407-0397. For other helpful resources, check out our IBAG Video Resources, Frequently Asked Questions about Vacuum Workholding, or High Speed Spindle Frequently Asked Questions.

Download the Witte Vacuum Products Catalog