Click image to enlarge

High-Speed Spindle Repair Services

At the heart of CNC machinery, as well as other popular production tools, including lathes, mills, and grinders, high-speed spindles offer the capabilities to transform materials into precision components. However, their long operation periods can lead to general wear, causing a host of challenges that may indicate a defective spindle, such as higher operating costs or reduced production. If left unrepaired, a defective spindle can cause total machine failure. IBAG North America offers precision CNC spindle repair to provide spindle system solutions that maintain the quality and performance of your operations. Contact IBAG North America to learn about our advanced repair capabilities or submit a service request for your equipment.

Service Request

After testing, a trim balance may be conducted to optimize spindle balance, or the spindle may receive a taper re-grind to achieve the necessary run-out accuracy, thus completing our comprehensive spindle repair services. To ensure timely repairs and fully authorized warranties, please follow our spindle shipping instructions.

Service Request

Advantages of CNC Spindle Repairs

High-speed CNC spindle repair services from knowledgeable and experienced technicians who understand your critical equipment offer a range of benefits to your operations, as well as your machinery, including:Minimize Downtime

Broken or worn spindles can cause critical operational issues, slowing down or rendering machinery inoperable. We implement focused CNC spindle repair methods to repair or rebuild spindles, getting machines back up and running for production success and minimizing downtime to avoid lost revenue.Lower Operational Costs

When spindles are broken or worn out, they may still function, despite issues with their operation. Machines using defective spindles will operate significantly slower and less efficiently, resulting in higher operating costs and reduced production. We repair or replace all malfunctioning components to return your machines to peak performance.High-Quality Solutions at Cost-Effective Prices

By focusing on the specific damaged components rather than replacing the entire unit, spindle repair can offer significant cost savings compared to replacement. Our comprehensive repair and rebuilding services are designed to address spindle defects at their source and test the quality of your repairs to ensure they withstand rigorous use.Spindle Repair Services for IBAG-Brand Spindles

IBAG North America offers a wide range of high-speed spindles, accessories, and tooling to support various industries with precision solutions. With expertise and experience tailored to IBAG spindle products, our high-speed CNC spindle repair services are for IBAG spindles only. Spindle repair services require extreme precision, specialized knowledge, and diagnostic skills to prevent mistakes that may lead to catastrophic machine damage, safety hazards, and repeat repairs. IBAG North America offers combined expertise spanning decades to deliver reliable CNC spindle repairs, ensuring your equipment runs smoothly for years to come.Our High-Speed CNC Spindle Repair Process

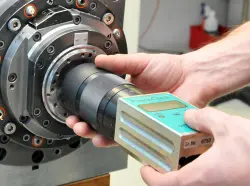

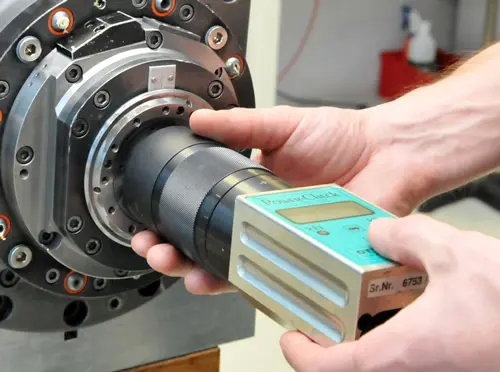

We offer repair, retrofitting, and rebuilding services for all IBAG high-speed spindles. Spindle repair services, including bearing replacements, balancing, as well as run-in and vibration testing, are completed at our state-of-the-art facility in North Haven, Connecticut. The premium CNC spindle repair process from IBAG North America follows these steps:- The spindle undergoes a thorough evaluation to determine the spindle condition and the suspected cause of failure. Photos are taken and observations are recorded in a repair report. We will then provide a detailed cost proposal, including all parts and labor required for the project.

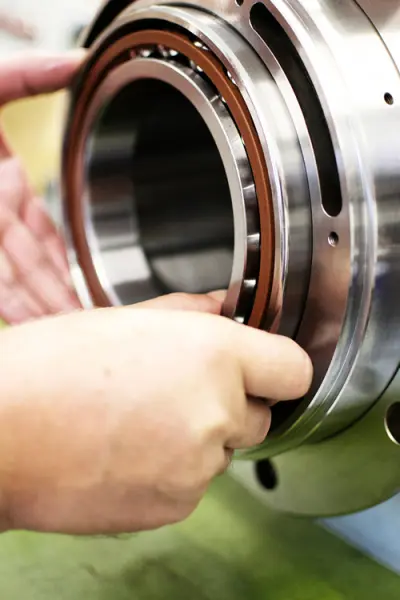

- Once approved, the spindle is disassembled, and internal parts are assessed for wear. Then, the internal spindle components are cleaned in a hot, ultrasonic cleaner and dried.

- If necessary, the spindle rotor shaft is checked and rebalanced to less than a G1 level with a precision balancer.

- The spindle is reassembled with new parts and bearings following exclusive procedures set forth and required by the factory. Following reassembly, the spindle enters a test field area for run-in, trim balancing, and final testing.

After testing, a trim balance may be conducted to optimize spindle balance, or the spindle may receive a taper re-grind to achieve the necessary run-out accuracy, thus completing our comprehensive spindle repair services. To ensure timely repairs and fully authorized warranties, please follow our spindle shipping instructions.

Spindle Motor Repair, Replacement Parts, and Supplies

In addition to our spindle repair services, all spindle system tooling and accessories are supported by our repair and spare parts capabilities, including:- High-Frequency Spindle Drives

- Spindle Chillers

- High-Speed Spindle Bearings

- Spindle Bearing Lubrication Systems

- And More

Contact Us for IBAG High-Speed CNC Spindle Repair Services Today

IBAG North America operates a high-technology facility in North Haven, Connecticut. With decades of experience in manufacturing high-speed spindles and spindle components, we have the expertise to support you with superior application engineering and premium repair services for CNC spindles, as well as Witte vacuum workholding repairs, provided by expert technicians. Contact us with any questions about our spindle repair services or submit a service request to get started.