IBAG Advanced Precision High Speed Spindle Tooling Systems

Every high speed spindle needs a tool to be effective. It could be a milling cutter, drill, or grinding wheel. There are also different tooling system options, ranging from a precision collet to grinding arbors. If your application requires multiple tools, quick-change tool holder systems are also available at IBAG North America.

Learn more about Tooling and accessories available, or contact us to discover how a high speed spindle tooling system can help with your specific application.

For some spindles, a modified BT30 type tool holder without drive key slots is used. On large spindles, CAT50, BT50 and ISO50 tooling options are offered.

Learn more about Tooling and accessories available, or contact us to discover how a high speed spindle tooling system can help with your specific application.

CNC Tool Holding System Options

High speed spindles must have a means of accurately holding their CNC milling or cutting tool. Depending on the application and accuracy requirements, there are various tooling systems that can be used. IBAG high speed spindles utilize a variety of tool clamping methods, including CNC milling components and other tool holder systems.Precision Collet Systems & Components

Used on smaller spindles, precision collet systems, like ER8 and ER11, provide a means to clamp small diameter tool shanks manually.Manual Collet Tool Holders

The Mega 3S and Mega 4S are also manual collet systems; however, they feature an extremely high accuracy. These systems require the operator to change cutters with a set of wrenches.Automatic Tool Shank Unclamping

Used on medium sized spindles, the P9 and P10 collets are for automatic tool shank unclamping. The P type collet is opened by a pneumatic cylinder, which is located on the IBAG high speed spindle. These collets don’t require any operator intervention.Fully Automatic Spindle Tooling Systems

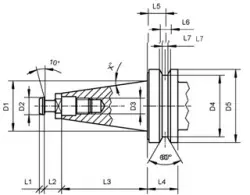

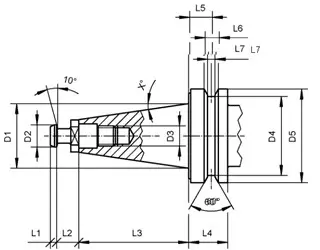

Fully automatic tooling systems utilize removable tool holders. They are available on all IBAG tool changing (A-Type) spindles with diameters of 60 mm or larger. These systems include the IBAG SKI, our patented system, and a full range of HSKE/A tool holder sizes.For some spindles, a modified BT30 type tool holder without drive key slots is used. On large spindles, CAT50, BT50 and ISO50 tooling options are offered.