Click image to enlarge

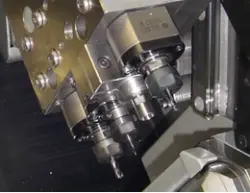

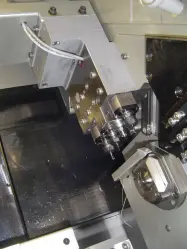

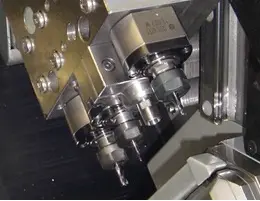

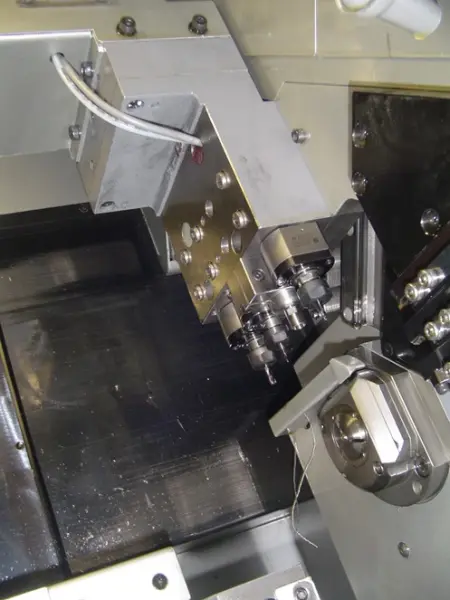

Custom High Speed Spindle CNC Machine Integration

IBAG spindles are a perfect solution to convert your CNC machine to a high speed production center. Proper machine integration requires the knowledge and experience to make the appropriate mechanical and electrical modifications that will result a safe, productive, and reliable system. For over 25 years, IBAG North America has successfully completed over 125 machine integration projects on both new and existing CNC machines. Contact IBAG with your project requirements today.

Advanced Features for CNC Machine Spindle Integration:

- Many IBAG spindles available to suit your CNC machining center application.

- Complete machine integration including CNC and full ATC functionality.

- Most CNC types completed, including Haas, Mazak and more.

- Auxiliary spindle integration possible for side-mount and other special needs.

- IBAG handles the full project – design, fabrication and installation.

- Options include coolant through the tool, orientation and tapping.

- Rugged, reliable system with a one year warranty.

Custom CNC Machine Integration Process

IBAG machine integration begins with a thorough evaluation of the customer’s application. Based on the application requirements, the proper spindle system, including spindle power, speed, and tooling, will be selected. The next step is to design and fabricate the mechanical components required to install the IBAG spindle and ATC parts required for the conversion. At the same time, a complete review and analysis of the electrical CNC interface with the machine control must be completed. The IBAG spindle system must connect to the CNC for operation and safety. When completed, the IBAG spindle machine integration will allow fully automatic spindle control, including direction and speed, and complete ATC operation. No permanent changes are made to the machine tool, so that if desired, the standard spindle can be reinstalled in the future.CNC Milling Machine Integration Options

Many machine types have been successfully integrated, including Haas, Mazak, Mori Seiki, Boston Digital, Hurco, Mitsui Seiki, Hitachi Seiki, Makino, Bridgeport, Fadal, and more.Special machine integration, including mounting auxiliary spindles to CNC machines, is also possible. Often, the standard machine spindle will be retained to perform roughing and semi-finishing, and an IBAG high speed micro spindle, small spindle, medium spindle, large spindle or Plug-N-Go spindle is needed to perform finishing or engraving operations. IBAG high speed spindles can be mounted in a fixed position on the head, or on a movable slide, controlled by the CNC.

Contact IBAG North America for High Speed CNC Machine Integration Today

Contact IBAG or get a quote started and discover how your standard CNC can be converted to become an IBAG high speed production center. IBAG North America is the only single-source, high speed spindle manufacturer that can support the complete project – design, fabrication, and installation. Give us a call today at 203-407-0397 with your unique application requirements. For other helpful resources, check out our IBAG Video Resources or High Speed Spindle Frequently Asked Questions.View IBAG Taylor Made Custom Spindle Project article